- Material:12k T400 carbon fabric

- Weight:200, 300, 400gsm etc.

- Function:Construction reinforcement

Carbon fiber building reinforcement fabric is a modern structural material composed of carbon fiber and resin. It is constructed on the construction site through wet paving or heat curing paving

- Material:100% Carbon Fabric

- Weight:200GSM

- Function:exterior and interior fabric for sports equipment, automobiles, furniture decoration, etc.

- Color:Black

The warp and weft of the plain weave carbon fabrics are interwoven in a regular pattern, are mainly used for drones, sports equipment, automobile, medical devices, etc.

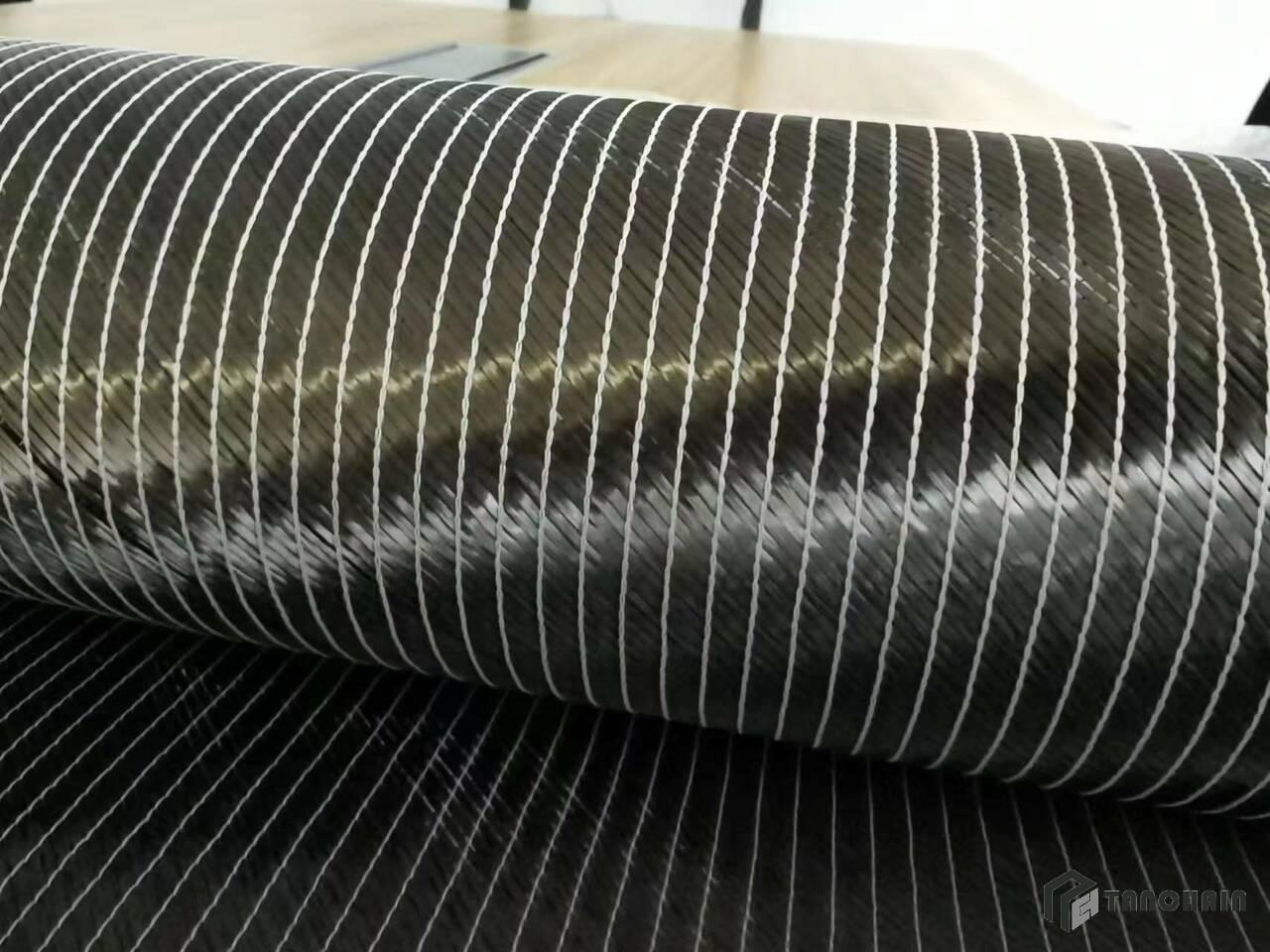

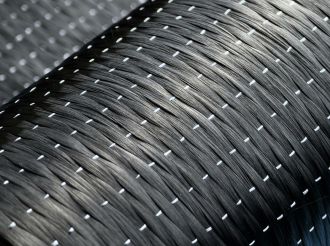

- Material:12K carbon fiber

- Weight:200g,300g,400g etc.

- Function:reinforcement

The advantages of using carbon fiber non-Crimp, biaxial fabrics are more prominent, and composite products with light weight, high strength, and better mechanical properties can be obtained.High strength to weight ratio.

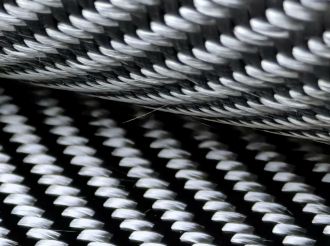

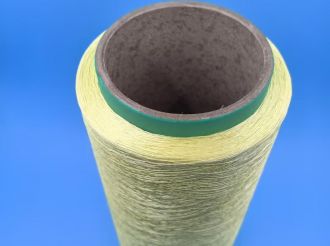

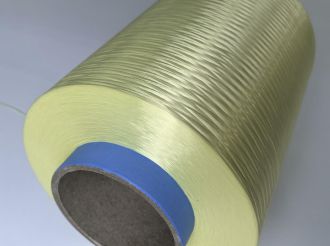

- Material:100% Polyacrylonitrile(PAN)

- Weight:1k 3k 6k 12k 25k 35k 50k

- Function:The precusor of carbon fiber

- Color:white

PAN fiber are the chemical precursors of carbon fibers. PAN is first thermally oxidized in air at 230 °C to form oxidized PAN fibers, which are then carbonized in an inert atmosphere at temperatures above 1000 °C to make carbon fibers

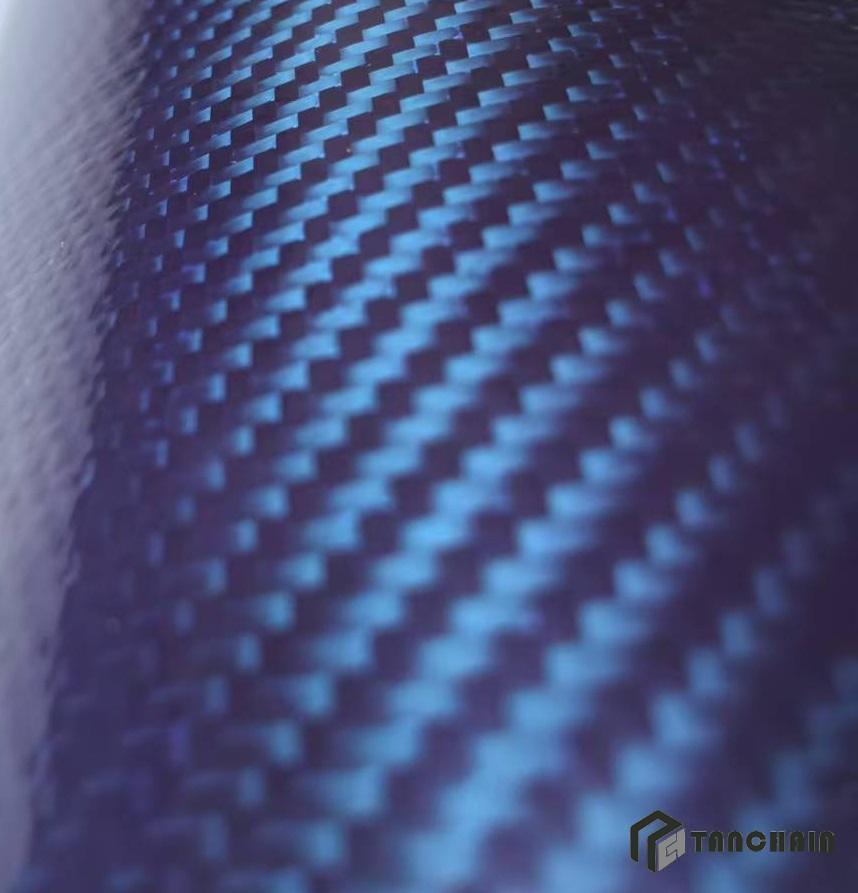

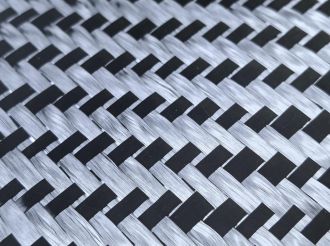

- Material:100% Carbon Fiber

- Weight:200gsm

- Function:High strengh, Low weight, Good looking, High modulus

- Color:Black

The twill carbon fiber fabrics have an oblique pattern that has a certain angle with the arrangement direction of the carbon fiber bundle. There is no carbon fiber bundle in the direction of the pattern.

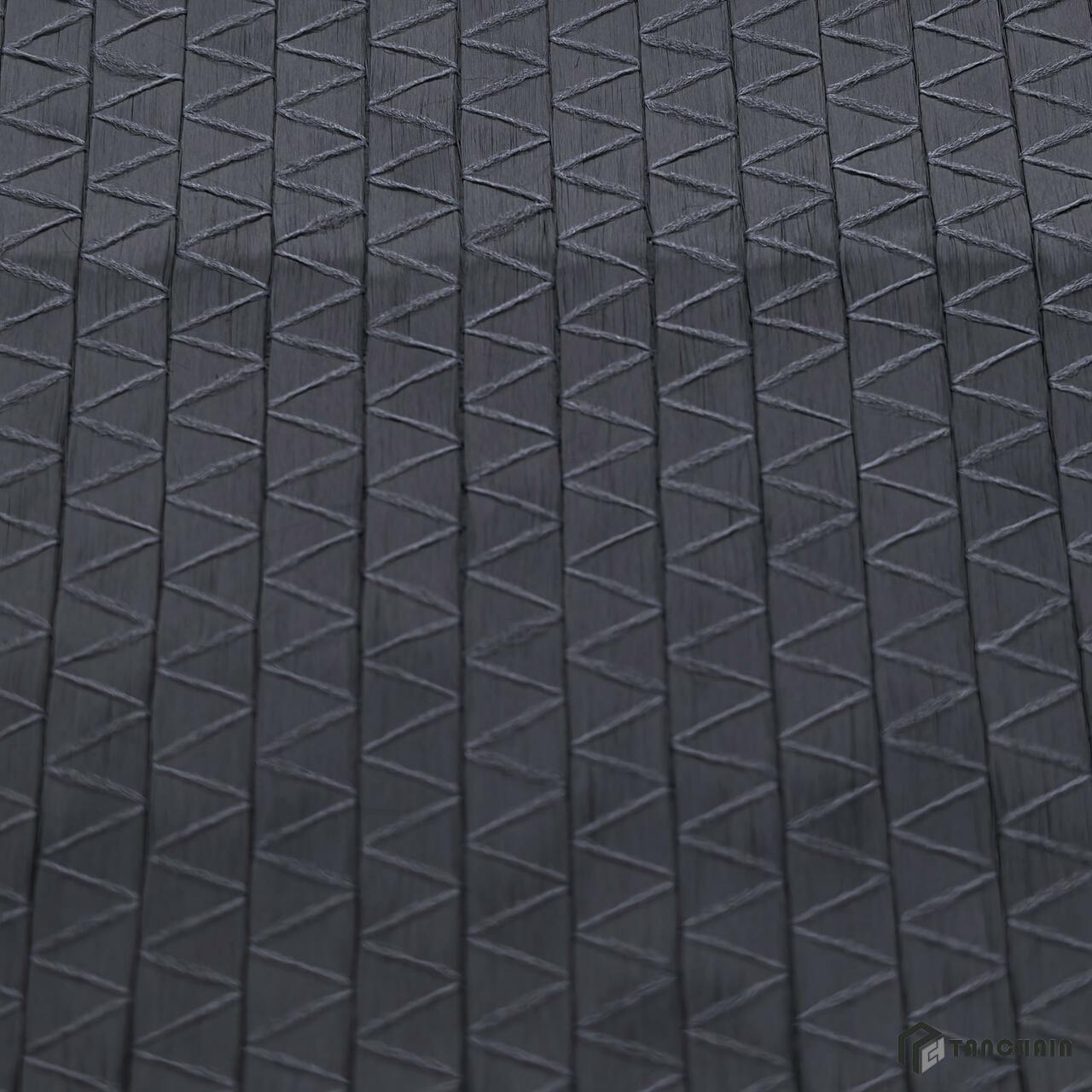

- Material:12K carbon fiber

- Weight:600g

- Function:Reinforcement, boat construction etc.

Carbon fiber triaxial fabric is a kind of high performance composite material, it has excellent mechanical properties and durability, is composed of the first fiber bundle, the second fiber bundle and the third fiber bundle.

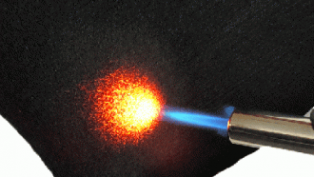

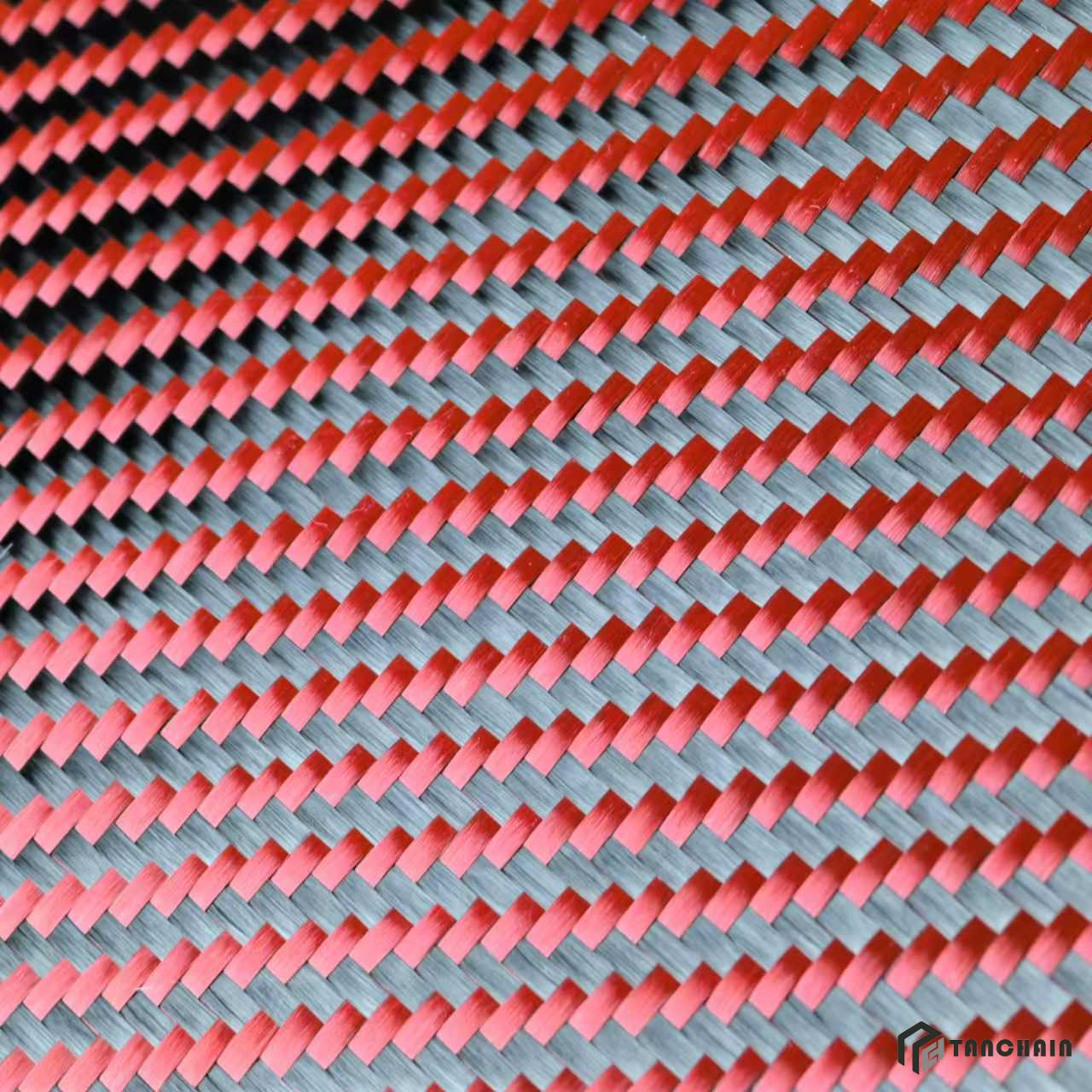

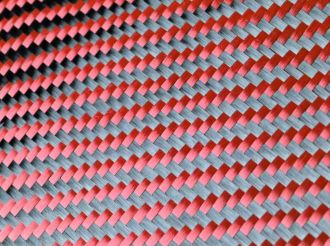

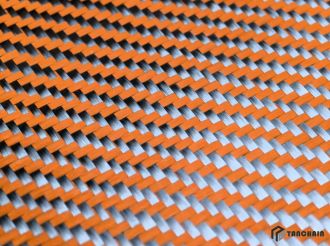

- Material:50% Carbon fiber, 50% Kevlar

- Weight:200gsm

- Function:High Temperature Resistant, High Strength, Flame Retardant, Fire Retardant, Waterproof, Anti-Static

- Color:Red

Hybrid Fabrics are made from more than two different fiber materials (carbon fiber, aramid fiber, kevlar, basalt fiber, glass fiber and other composite materials) from the composite

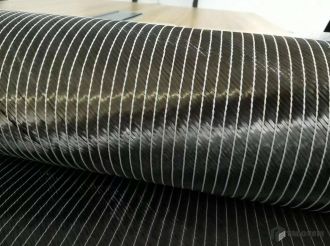

- Material:12k T700 carbon fabric

- Weight:80g, 100g, 160g, 200g, 240g etc.

- Function:Reinforcement, exterior, surface

Spread tow carbon fabric can achieve a very beautiful appearance while ensuring the strength of the carbon fabric and saving the amount of carbon fiber.

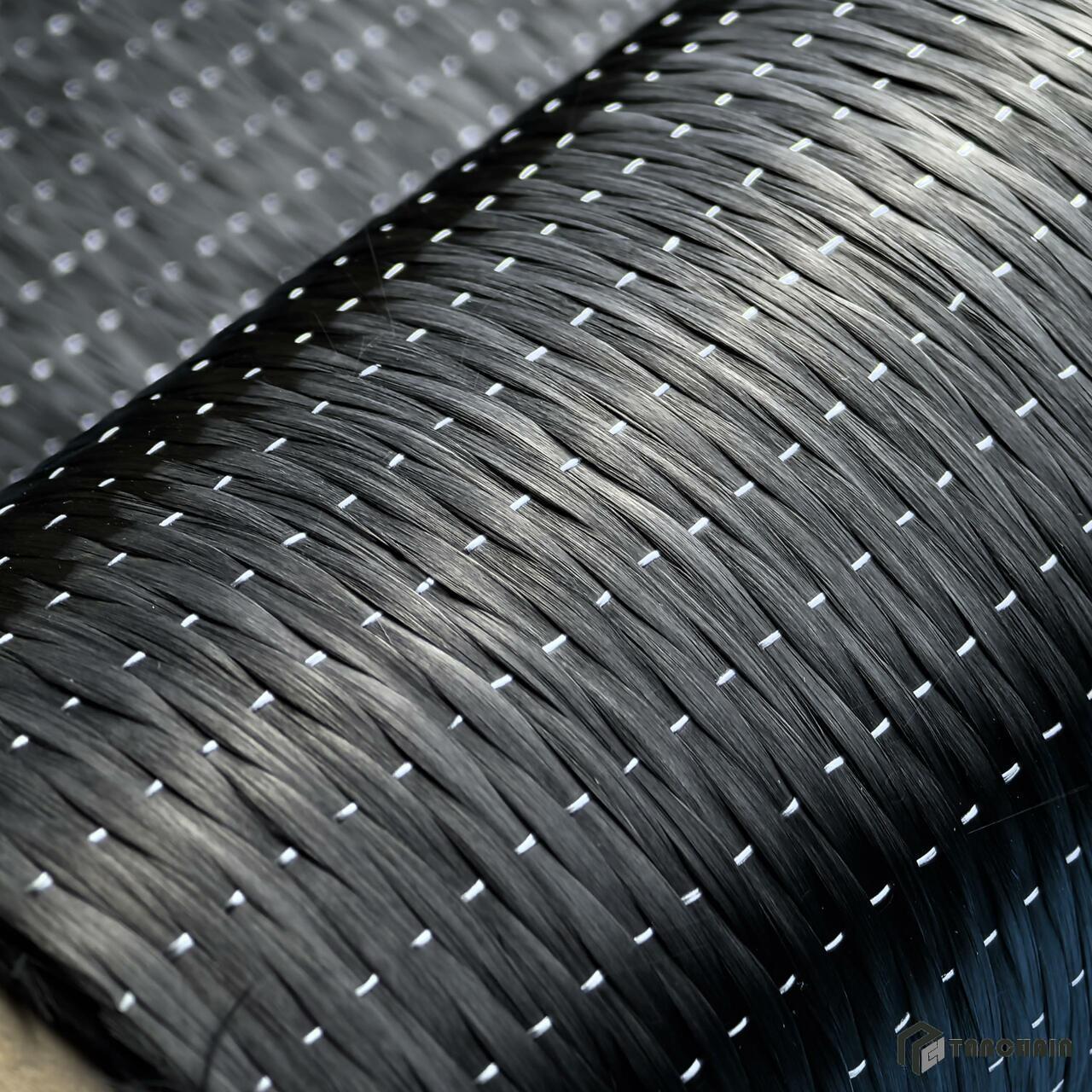

- Material:100% Carbon Fiber

- Weight:25k filaments

- Function:High strength, Low weight.

- Color:Black

25K carbon fiber filament is a large tow carbon fiber product, can meet the high requirements of material performance in high-end application fields.

- Material:Carbon fiber

- Weight:1.6-1.7gram/cm3

- Function:High strength, Low weight.

3K carbon fiber board/sheet is a carbon fiber board made of 3K carbon fiber material.

- Material:60% Carbon Fiber Fabric, 40% resin

- Weight:330gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

Twill 3k T300 carbon fiber prepreg composed by 60% Carbon Fiber, 40% resin, and it is necessary to keep it refrigerated during transportation and storage.

- Material:Carbon fiber

- Weight:1.6-1.7gram/cm3

- Function:High strength, Low weight.

Carbon fiber tube is a tubular structure made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated, cured, pultruded (wrapped)

-

-

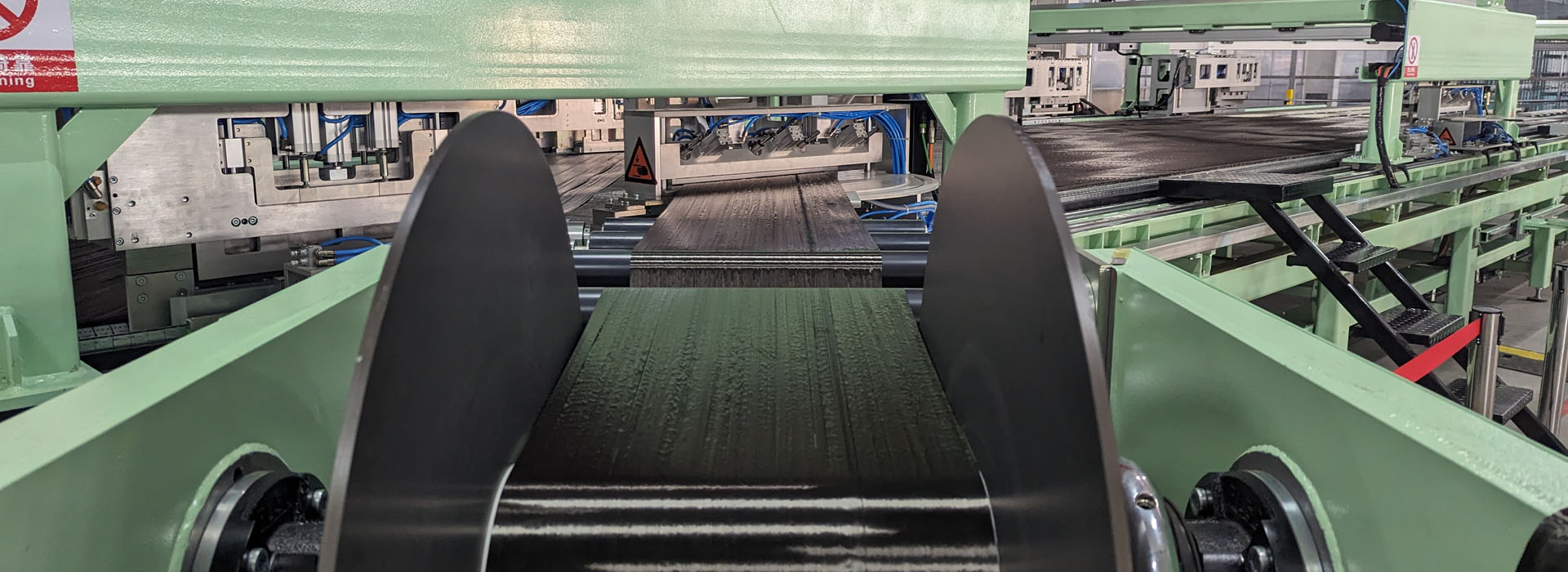

ABOUT US

- Shanghai Tanchain New Material Technology Co., Ltd. is a high-tech enterprise integrating research and development, production and sales, we focus on high strength, flame retardant, heat insulation and high temperature resistant products, mainly including functional textile products such as yarns and fabrics woven from pre-oxidized fibers, carbon fibers, aramid fibers, PTFE, etc. Our products are widely used in industry, transportation, automobile, protection and other industries.With more than 8 years of experience in producing innovative products for extreme protection and labor protection applications, tanchain has grown to become one of the leading suppliers in the Chinese technical textile market with our significant sourcing and technology advantages. We have a complete industrial chain and strict quality management system. Tanchain from dozens of domestic and foreign first-class raw material suppliers carefully selected raw material suppliers, and signed a long-term supply agreement, to ensure that we get a large number of high-quality raw materials in time, but also the fundamental guarantee of the quality of our products. We have set up high standard modern factories at home and abroad, and hired managers and technicians with first-class working experience from domestic and foreign companies to ensure that our products have their own technical advantages and market competitiveness. Good products enable us to obtain a large number of customers in the domestic and foreign markets, these quality customers are our company's precious resources.Excellent customer groups provide us with feedback and improve the function and quality of our products. Quality control department was set up at the beginning of the company, and the chairman of the company attached great importance to quality control.We invest a lot of money to ensure the quality of our products, which is the basis of our long-term foothold in the market.The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products. Every process follows scientific norms and keeps improving. Our mission is to be recognized as a major supplier in the market by providing high quality yarns, fabrics and other textile products to meet the needs of our customers.Our mission will be achieved through outstanding customer service, sales and manufacturing, and teamwork by all of our employees.We will continue our tradition of honesty, fairness and integrity in our relationships with our customers, employees, communities and stakeholders.