-

-

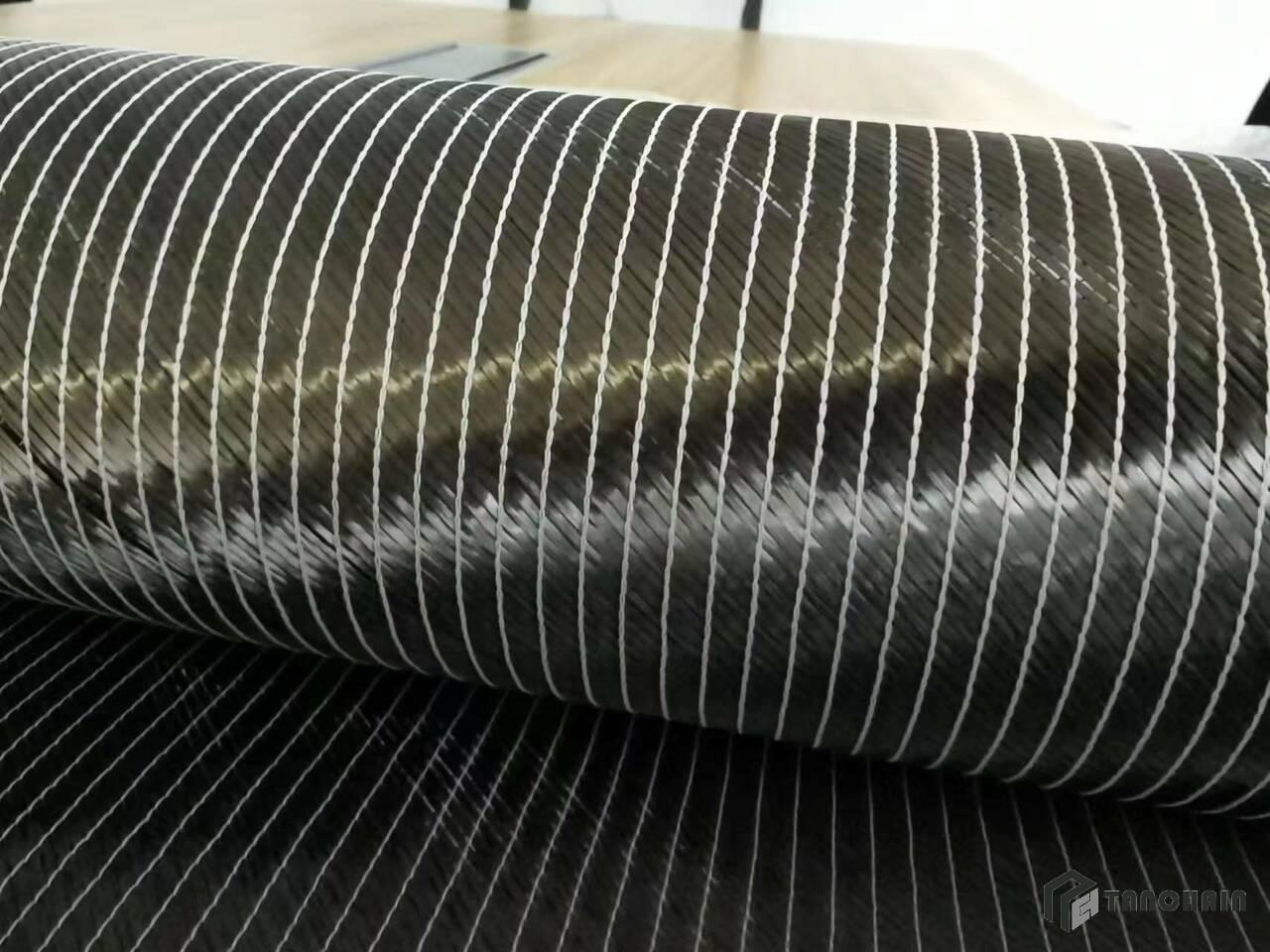

200gsm - Biaxial carbon fiber fabric - +45/-45 Non-Crimp-6oz

- Code:TC-CF-X200B

- Material:12K carbon fiber

- Weight:200g,300g,400g etc.

- Function:reinforcement

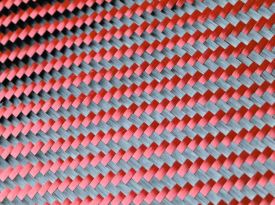

- Weave:Biaxial,multi-axial,triaxial,Non-Crimp

- Width:127cm 254cm

SEND INQUIRY

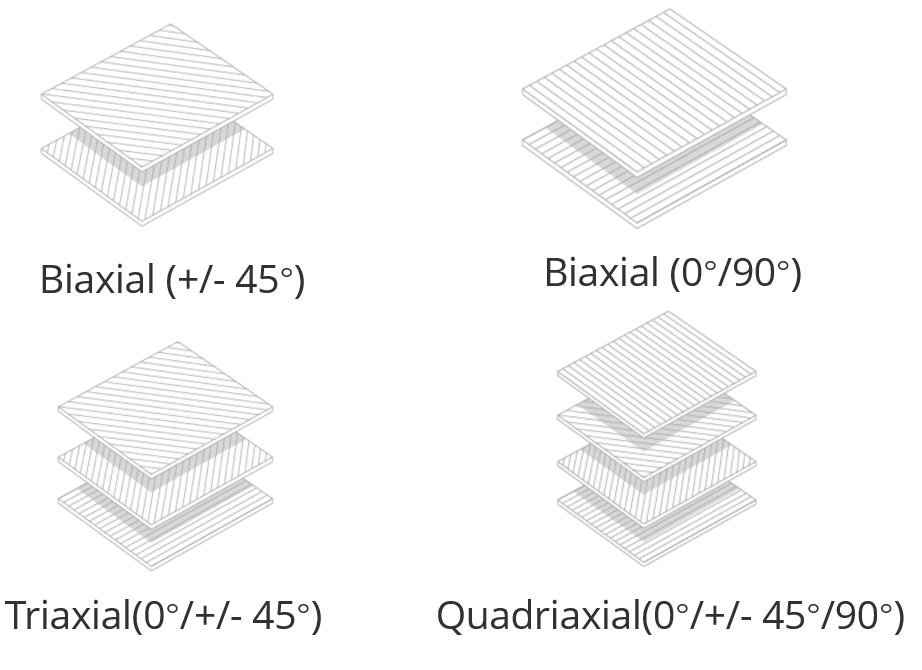

Characteristics of biaxial/multi-axial/tri-axial/quad-axial carbon fabric:

Carbon fiber axial fabric is a base cloth fixed together by a knitting system or chemical adhesive. It consists of one or more layers of parallel straight carbon fiber yarns. Each layer of yarns can be arranged in different directions. The layers of yarn can vary in density and be combined with fiber mesh, film, foam or other materials.

Axial carbon fiber fabric is a basic fabric fixed by a fabric system or chemical adhesive. It consists of one or more parallel layers of direct carbon fiber tows. Each layer of yarn can be arranged in different directions.

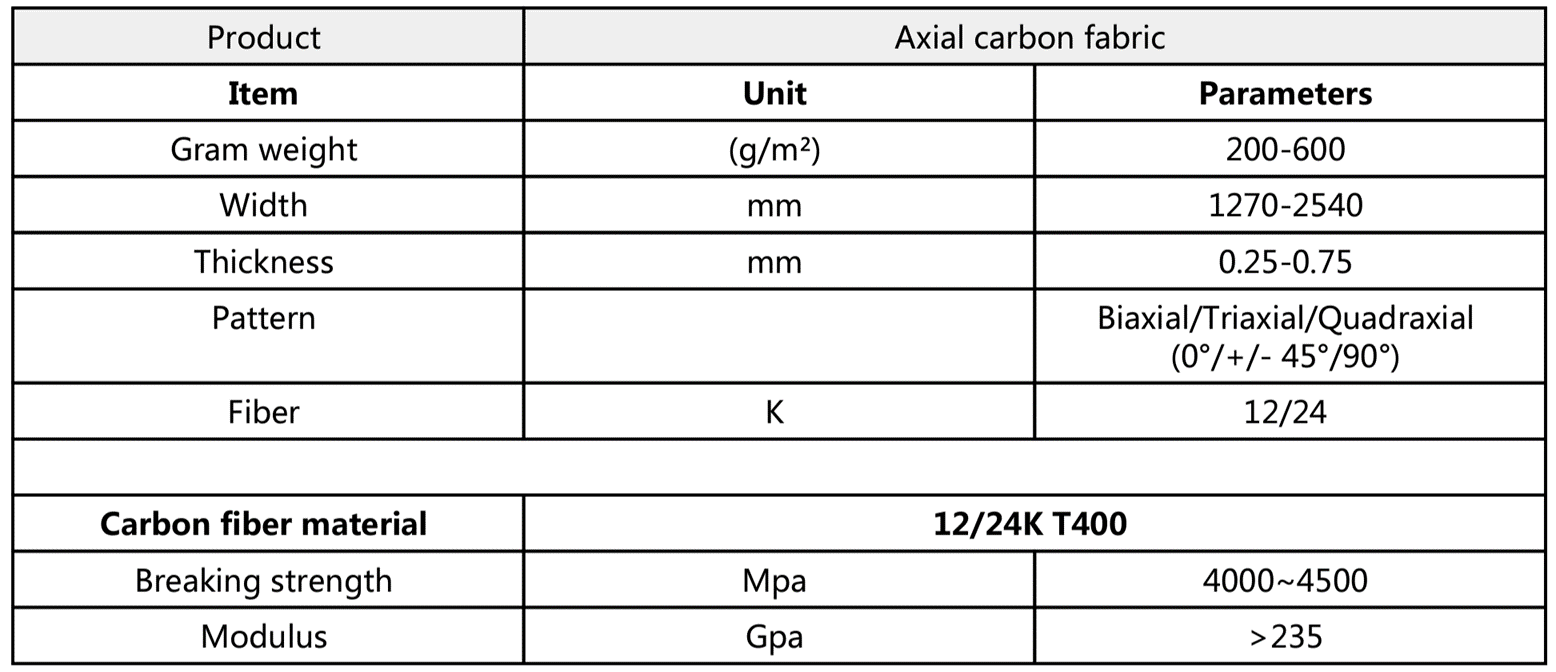

Properties of Axial carbon fabric

•Good Stability: Due to the fact that axial fabrics are a special structure formed by interweaving multi fiber tows, the structural stability of the fabric is good.

•Strength and stiffness in multiple orientations: The multidirectional arrangement of carbon fibers enables the strength and mechanical properties in all directions are the same. Designers and engineers can tailor the material’s properties according to specific load requirements, resulting in optimized structural performance.

Parameters of axial carbon fabric

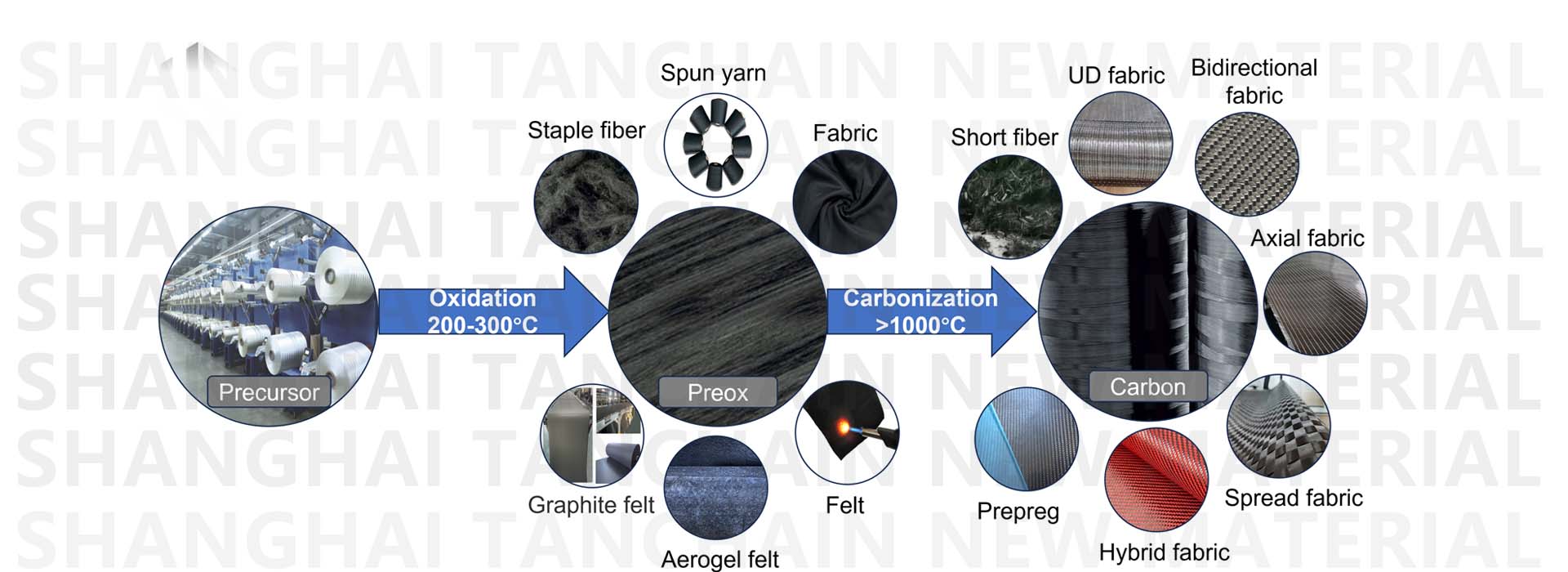

Tanchain's Production Flow

Product line for axial carbon fabric:

Shipping:

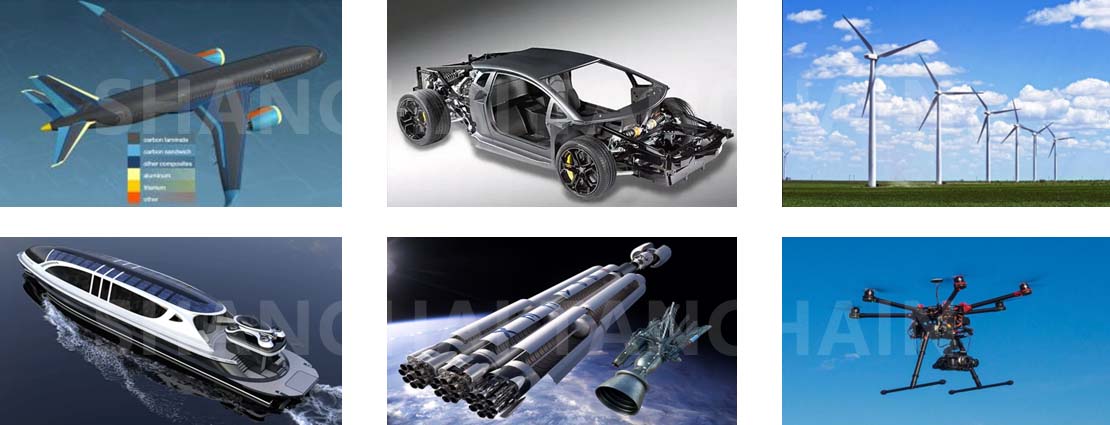

APPLICATIONS