- HOME

-

PRODUCTS

- ALL

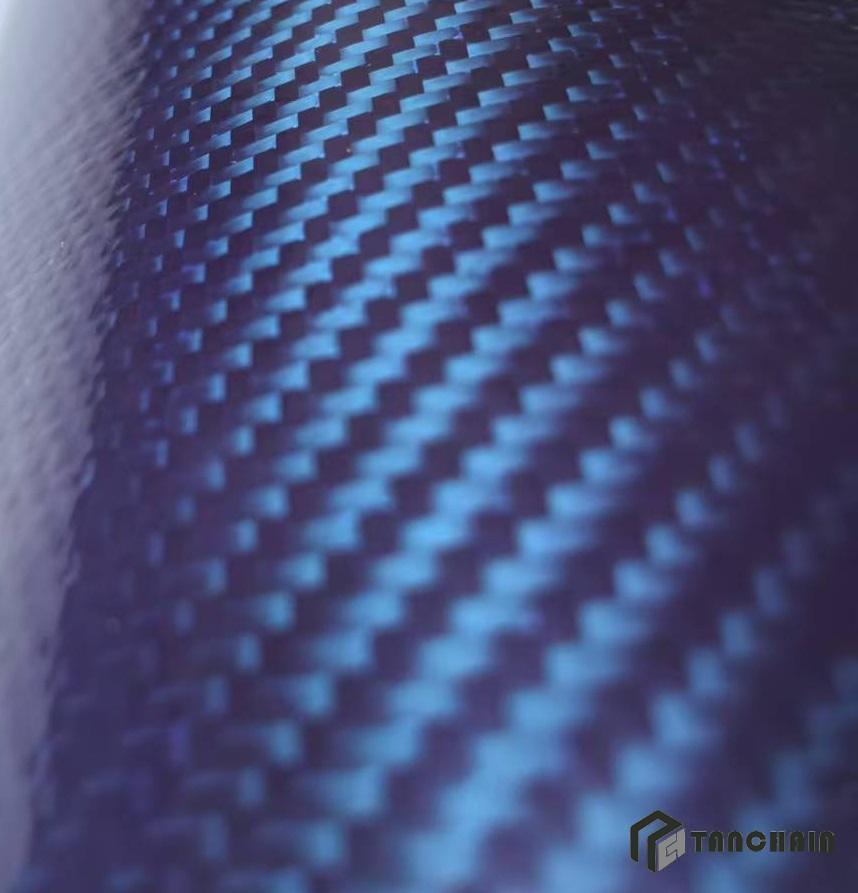

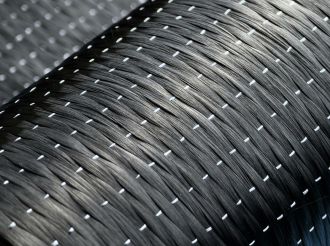

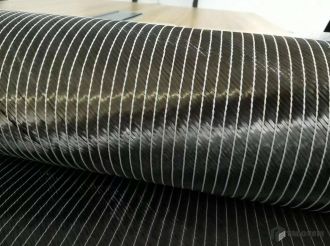

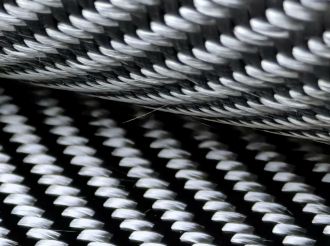

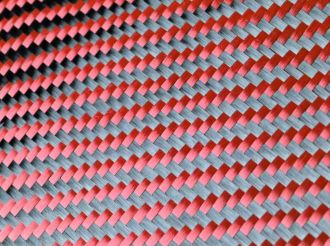

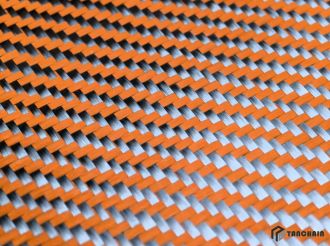

- Carbon Fiber Series

- Oxidized Series

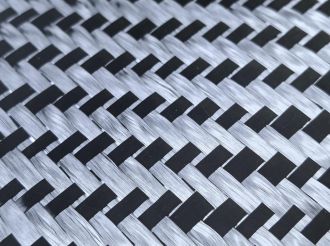

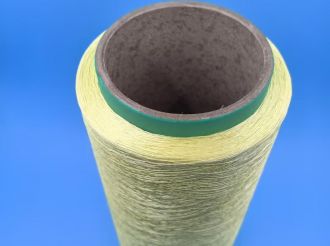

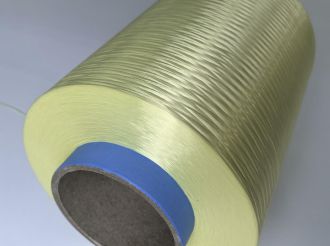

- Aramid Series

- Other

-

APPLICATIONS

- Case

- Solution

- FAQ

- Unit Converters

-

NEWS

- Tradefair

- Media

- Information

-

ABOUT US

- Profile

- Vision

- Mission

- Responsibility

- Contact us