What is modulus and the application of high modulus carbon fiber in aerospace?

- 2022-04-22

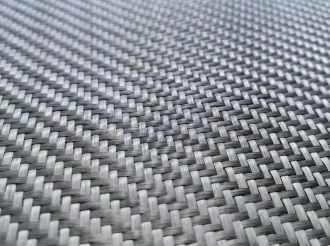

Carbon fiber is widely used in the aerospace field. In terms of components, carbon fiber is a general term for a type of fiber with a carbon content of more than 95%, which has a very high specific modulus and specific strength. Among them, high-strength carbon fiber refers to fibers with high strength (strength greater than 4.5GPa) and moderate modulus (modulus is generally 230GPa to 310GPa), while high-modulus carbon fiber has a carbon content of more than 98% and a modulus of at least 370GPa, but the strength tend to be low. If you have no concept of modulus and strength, you can understand it like this: a stick of the same thickness, with both sides fixed horizontally, with a weighing weight hanging in the middle, at this time, the middle of the stick will bend down. For the same weighing weight, the higher the stick modulus, then The less the stick bends down. How to understand strength? It is still this stick, the weight in the middle is added to 50kg, and the stick is broken. Then, 50kg divided by the cross-sectional area of the stick is the strength of the stick.

Are stronger materials stronger?

For structural materials it is not so simple. For example, if a building has been used for a long time and some beams and columns are damaged, the stiffness of the building will be poor, and the stiffness here corresponds to the modulus. If the stiffness of a structure is poor, under the same external vibration, the resonance frequency of the object will become lower, so it is easy to resonate with the external vibration source, and the vibration of the resonance is harmful to some extent. In order to improve the rigidity of the building, a relatively simple method is to reinforce, thicken the columns and increase the rigidity.

The same is true for aerospace vehicles.

In order to make missiles, rockets, and drones reach their targets accurately and stably, it is necessary to ensure the stability of the aircraft during flight. That is to say, "the body must be rigid." So, how to solve it? One of the methods is to make the structure thicker, and the material of the projectile body should be selected with high modulus and thick material, so that the resistance to deformation is strong. However, spacecraft are required to be lightweight, which is a contradiction. At this time, it is necessary to choose light and strong materials, such as carbon fiber powder. At present, many models still use high-strength carbon fiber, that is, carbon fiber with high strength and low modulus. Because this type of carbon fiber can meet the design requirements. However, in some cases, high-strength carbon fibers have excess strength and insufficient modulus. For example, large aspect ratio wings and space vehicle support structures all have one thing in common. The slenderness ratio of the structure is very high, and it is easy to vibrate when it is disturbed during flight. When the frequency of vibration is close to the natural frequency of the structure, the Resonance will occur, which will obviously affect the stability of the aircraft. In order to limit the resonance, it is necessary to increase the low-order natural frequency of the structure, so that no or less resonance occurs during the flight. In order to increase the natural frequency, it is necessary to increase the stiffness of the structure. These applications therefore place very high demands on structural rigidity, as well as stringent weight and volume constraints. At this time, structural designers will "invite" high-modulus carbon fiber to appear. By using high-modulus carbon fiber, the rigidity of the structure can be improved while ensuring the strength under the limited structural weight, making the aircraft more stable. Therefore, we can say that it is the high-modulus carbon fiber that gives the spacecraft its "steel bones".