Aramid insulation paper

- 2022-11-24

Insulation materials are divided into solid insulation materials, liquid insulation materials and gas insulation materials. As a solid insulating material for electrical equipment, paper has a long history and is widely used in various electrical equipment such as cables and coils.

Due to the special use of insulating paper, it must have some characteristics different from other paper types, mainly including mechanical properties, electrical properties and thermal stability. Mechanical properties mainly include tensile strength and elongation at break; electrical properties mainly include dielectric strength, dielectric constant, dielectric loss, resistivity, etc.

According to different raw materials, insulating paper can be divided into three categories: plant fiber paper, mineral fiber paper and synthetic fiber paper. Among them, synthetic fiber paper represented by aramid insulating paper is the most popular and successful.

Aramid insulation paper

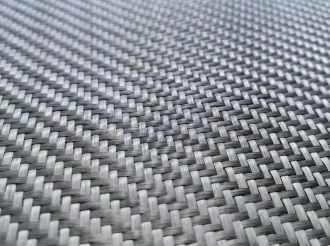

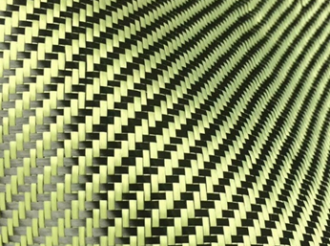

Aramid paper-based insulating material is a kind of non-woven fabric formed by a certain proportion of aramid chopped fiber and aramid precipitated fiber through wet papermaking and hot calendering. Interdisciplinary high-tech products have excellent performances such as light specific gravity, high temperature resistance, good insulation performance, flame retardancy, and long-term use in harsh working conditions. , one of the key basic materials in the fields of rail transit and so on.

DuPont of the United States invented meta-aromatic polyamide fiber (Nomex) in the 1960s, which is called aramid fiber 1313 in my country and put into use. It has good thermal stability, electrical properties, mechanical strength, chemical compatibility and adaptability. and other characteristics. It has broad market prospects, is widely used in military industry and electrical industry, and is an excellent insulating material of H class.

Aramid paper has long-term thermal stability, and its service life is longer than that of industrial organic high-temperature-resistant paper; it has good flame retardancy, and will not burn, melt or produce droplets in the air, and only works at extremely high temperatures (>370°C) It just begins to decompose; the electrical insulation performance is excellent, with a low relative permittivity and dielectric loss factor, which can make the insulation electric field distribution more uniform and the operating dielectric loss smaller; it is made of high-strength meta-aramid chopped fibers, the structure Dense, smooth surface, good flexibility, good tensile and tear resistance; strong hydrogen bonding makes the structure stable, excellent chemical resistance, very stable to most other chemical reagents and organic solvents; resistant to β, α And x-ray radiation performance is very good.

In contrast, domestic aramid insulating paper still has shortcomings such as poor uniformity, poor heat resistance, and low strength. With the development of the electrical industry and the continuous improvement and upgrading of insulating materials, the performance requirements for aramid insulating paper are also increasing.

Advanced Aramid Insulating Paper

1. Dense structure aramid insulating paper

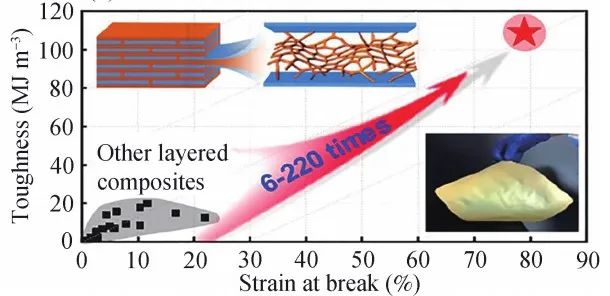

The traditional aramid insulating paper structure uses chopped fibers as the main skeleton material, and partially microfibrillated precipitated fibers as the filling and wrapping materials. The two have a large dimension difference, and the surface and cross-section of the aramid insulating paper present a loose and porous structure. The "open" structure results in weak interfacial bonding and poor strength of the aramid paper. The structure of imported aramid insulating paper presents a very dense "closed" structure with low porosity and fewer defects, showing better electrical insulation performance.

Therefore, optimizing the three-dimensional structure of aramid insulating paper by various means, improving the bonding strength of the fiber interface, and realizing the densification of the microstructure of aramid insulating paper will help improve the comprehensive performance of domestic aramid insulating paper.

2. Corona resistant aramid mica insulating paper

Mica paper is excellent in insulation and chemical stability, and has excellent corona resistance. The aramid mica paper prepared from aramid fiber and mica makes up for the poor corona resistance of traditional aramid insulating paper, and the traditional pure mica paper needs glass cloth and adhesive reinforcement. It has the characteristics of both aramid and mica , with high temperature resistance, corona resistance and excellent strength properties.

3. Aramid nano insulating paper

Aramid nano-insulating paper can realize the thinning of the insulating layer and efficient heat dissipation. It can be used as an ultra-thin insulating layer and applied to the next generation of highly lightweight and integrated special electrical equipment to solve the problems of poor active heat dissipation and short service life of electrical equipment. , realize equipment miniaturization, integration and structural weight reduction, and promote the development of high efficiency and reliability of electrical insulation equipment.

4. High thermal conductivity aramid insulating paper

Designing and developing insulating materials with high strength and high thermal conductivity is the key to the development of miniaturization, light weight and integration of electrical insulation equipment. Polymer insulating materials are mostly poor conductors of heat, so thermally conductive fillers are usually added to the polymer matrix, mainly inorganic non-metallic fillers, among which BN has excellent mechanical properties and thermal conductivity, low dielectric constant and loss, is At present, it is an ideal filler for preparing high thermal conductivity insulating materials.