Glass Fiber Coated PTFE Production Process

- 2022-11-09

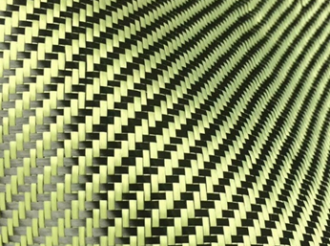

Glass fiber coated PTFE cloth is made of glass fiber cloth as the base material and impregnated with PTFE dispersion. The surface of the impregnated glass fiber cloth is coated with a thin layer of small fluororesin particles, and then after drying, baking, sintering and other processes, the dispersion liquid is volatilized to leave tetraoxide fine particles, which are tightly attached to the glass fiber cloth. In the surface and pores, it becomes a dense and continuous whole, which achieves the purpose of firmly bonding the glass fiber cloth and PTFE. According to different needs, inorganic or organic fillers can also be added to the dispersion to further improve its electrical properties, anti-aging properties and wear resistance, etc. After adding different pigments, it increases its excellent decorative properties.

handicraft Research

1. Raw materials

(1) Polytetrafluoroethylene (PTFE) dispersion

PTFE, commonly known as the king of plastics, is one of the best-performing varieties of plastics. It has excellent temperature resistance and corrosion resistance, excellent insulation performance, non-stick, non-toxic and odorless, and is harmless to human body.

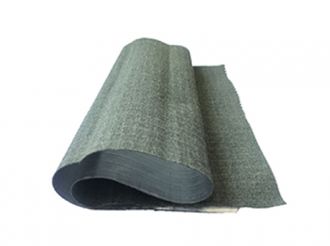

(2) The substrate of glass fiber cloth coated products should have high temperature resistance and good tensile strength. Compared with natural fibers and chemical fibers, glass fibers have the advantages of high strength, small elongation, and good chemical stability. Make up for the lack of PTFE and keep the size stable.

2. Production process and key technologies The main technical keys of the glass fiber impregnation tetrafluoro dispersion process are the following three aspects: tetrafluoro dispersion concentration, dipping temperature and speed

The concentration of the PTFE dispersion directly affects the surface finish, flatness, thickness and resin content of the product. The higher the concentration, the greater the thickness after each impregnation. The number of times of dipping can be reduced accordingly, but the tetrafluoride dipped in one time is too thick, and it is easy to cause cracks on the surface of the product after drying. In order to ensure the quality of the product, a low concentration dispersion should be used, preferably after multiple dipping.

The temperature distribution of the impregnation furnace is divided into three zones according to the facade, and the three processes of impregnation, drying and baking are completed respectively.

Low temperature zone: The temperature of the lower section of the dipping unit directly affects the surface temperature of the dipping tank, and is related to the number of defects such as bubble burst rate and flow marks on the liquid surface. Too high a temperature in this zone will dry the glass cloth dispersion too quickly, resulting in bubbles and flow marks. At the same time, the higher temperature in this area radiates to the bottom, causing the surface of the tetrachloride liquid to crust, and there will be tetrafluoro lumps on the surface of the impregnated glass fiber cloth, which seriously damages the quality of the cloth surface.

Medium temperature zone: When the impregnating cloth enters the second section in the middle of the unit, the evaporation of water should be gradually completed. If the temperature is too low, the evaporation of water will be incomplete, which will affect the effect of the next impregnation; The control of the temperature of the next section is hindered.

High temperature zone: When entering the upper third zone, the residual moisture on the cloth, the surfactant and the low content in the resin should be completely volatilized to facilitate the effect of the next impregnation process. If the temperature in this area is too high, it will cause local tetrafluoro sintering and affect the effect of the next impregnation. If the temperature in this area is too low, the cloth surface will be sticky, and the cloth layers will stick together during winding.

Although the impregnation unit is divided into three temperature zones from the bottom to the top, they are not completely separated, but are continuously gradual, and there is no obvious deviation between the zones. The transfer speed of glass fiber cloth dipping affects production efficiency and product quality. one of the key factors. The speed is slow, and the dispersion liquid evenly penetrates the cloth surface, which can avoid flow marks and reduce product defects, and the quality of the cloth surface is good. But the speed is too slow to reduce the production efficiency and increase the cost. The speed is fast, and defects such as bubbles and flow marks are easily generated, and the drying time is not enough, the drying is not clear, and the cloth surface is sticky.

Study on Sintering Temperature and Speed

Unlike thermoset resins, tetrafluoro resins do not have a "curing" stage, but must be sintered at high temperatures. The sintering furnace is divided into upper and lower layers, the lower layer further removes the surfactant and low molecular weight in the tetrafluoro resin, and the upper layer completes the "plasticization" process of the tetrafluoro resin. The temperature of the lower layer should be controlled to be lower, and the upper layer should reach the "plasticizing" temperature of the tetrafluoro resin, which is characterized by the immediate discoloration of the cloth surface, the white products changing from pure white to earthy white, and the black products changing from blue gray to jet black. If the temperature of the upper layer is too high or it stays at the plasticizing temperature for too long, the fabric will become brittle and the performance will be reduced.

The selection of the sintering speed must meet the temperature requirements. The sintering speed and temperature are two closely related factors, and the appropriate speed must be selected on the premise of meeting the temperature requirements. It is also impossible to complete the sintering without a standstill, whereas once the plasticizing temperature is reached, it only takes a few seconds to complete the sintering. Therefore, the faster conveying speed will not affect the plasticization. At the same time, the thickness of the glass cloth impregnated with PTFE is uniform and thin, so the heat transfer is rapid and it is easy to sinter.

Quality requirements for fiberglass base cloth

PTFE products have extremely high requirements on the quality of the base fabric, and the main factors affecting the quality of the products are the glass fiber base material and the technological maturity in the impregnation process. The base fabric is not allowed to have serious defects such as fabric wrinkles, yarn joints, broken yarns, and oil stains, and the quality requirements for fabric flatness and dense roads are also higher than those of general grey fabrics.