Common Types, Typical Characteristics And Main Applications Of Carbon Fiber Fabrics

- 2022-04-22

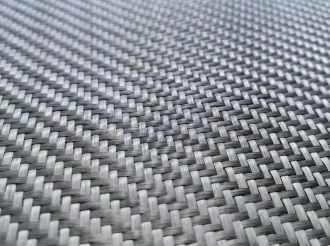

When used as a woven fabric, carbon fiber is usually used in the form of a woven fabric, which makes it easier to use and can provide additional structural strength according to application requirements. Therefore, carbon fiber fabrics have many different weaving methods, the most common of which are plain weave, twill weave and satin weave, which will be introduced in detail in this article.

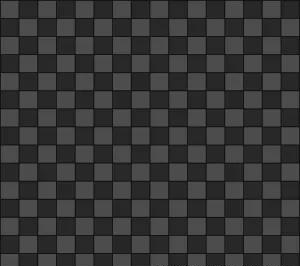

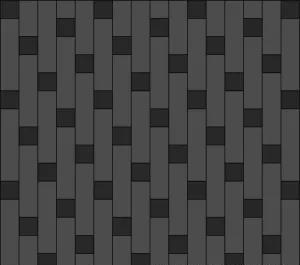

01. Plain weave fabric

The plain weave carbon fiber board has a symmetrical appearance and is in the shape of a small checkerboard. In this kind of braid, the tow is woven in an up/down pattern. The short spacing between the weaves gives the plain weave a high stability. Fabric stability refers to the ability of a fabric to maintain its weaving angle and fiber orientation.

Plain weave carbon fiber diagram

Due to this high level of stability, plain weave fabric is not suitable for laminates with complex contours, and it will not be as flexible as some other fabrics. Generally, plain weave fabrics are suitable for flat, tubular and two-dimensional curves.

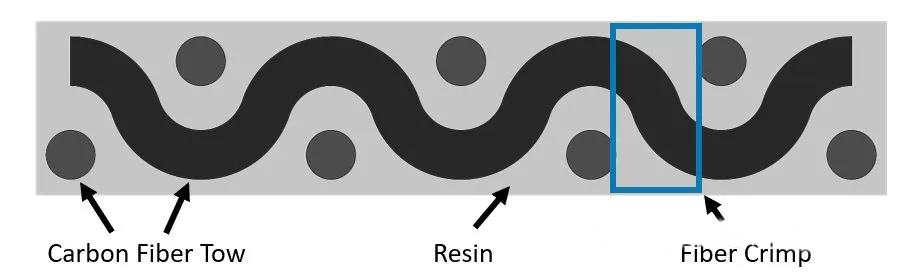

However, this kind of braid also has shortcomings. Due to the short distance between the interwoven fabrics, the crimp in the tow (the angle formed by the fiber during weaving, the crimp is shown in the figure below) is too large, and the rough crimp will cause stress concentration. Over time will weaken the parts.

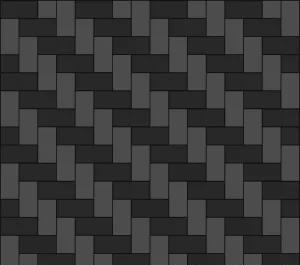

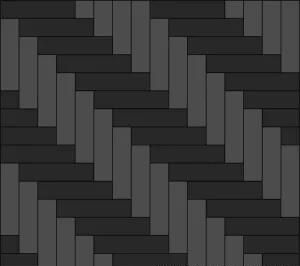

02. Twill fabric

Twill weave is the bridge between plain weave and satin weave. Twill fabric has good flexibility and can form complex contours. It can maintain the stability of the fabric better than satin fabric, but it is not as good as plain weave fabric.

If you walk along a tow in a twill weave, it passes through a certain number of tows, and then through the same number of tows. The up/down pattern creates the appearance of diagonal arrows, called "diagonal lines". Compared with plain weave fabric, the longer the distance between the two interwoven fabrics, the less crimp and the smaller the potential stress concentration.

2*2 Twill fabric

The 2×2 twill fabric is probably the most well-known carbon fiber fabric in the industry. It is used in many decorative structural applications, but it also has strong functionality. It has medium formability and medium stability. As the name 2×2 implies, each tow will pass through 2 tows and then through two tows.

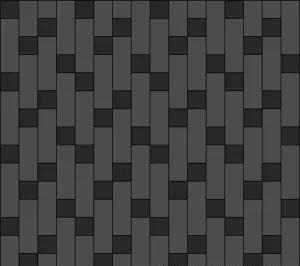

4*4 Twill fabric

Similarly, the number of tows of the 4×4 twill weave is 4 up and down. Compared with 2×2 twill fabric, its formability is slightly higher, because the fabric is not so tight, but the stability will be reduced.

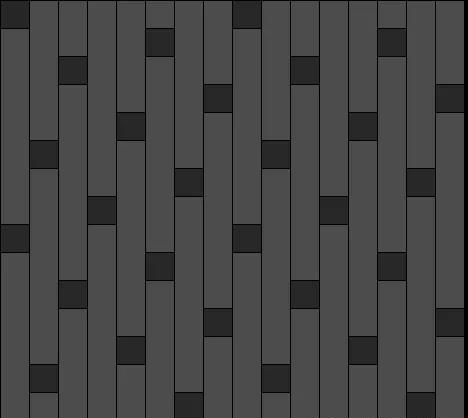

03. Satin fabric

Satin fabric has a history of thousands of years. It can be used to make silk fabrics with excellent drape while looking smooth and seamless. For composite materials, this drape means that it can easily form and wrap complex contours.

4 tow satin (4HS)

Due to the strong formability of the fabric, its stability is expected to be low. Common satin weave fabrics include 4 tow satin (4HS), 5 tow satin (5HS) and 8 tow satin (8HS). As the number of satin weaves increases, the formability will increase and the fabric stability will decrease.

(5HS)5 tow satin (4HS)

The number in the name of the harness indicates the total number of tow harnesses that have passed. In 4 tow satin (4HS), it will pass 3 upper pulls, and then pass 1 lower pull (three uppers and one lower). Similarly, in the 5 tow satin weave (5HS), it will pass the upper pull 4 times, and then in the 1 pass the lower pull (four up and one); while in the 8 tow satin weave (8HS), it will pass 7 The upper part is pulled again, and then the lower part is pulled through 1 time (seven up and down).

(8HS)8 tow satin (4HS)