How to Cut Carbon Fiber Composite Sheets

- 2022-05-07

Due to the high strength properties of carbon fiber composites, carbon fiber composite sheets are sometimes difficult to cut. In general, using a rotary tool is an easy way to cut most pipes and flats quickly and cleanly; a saw blade is a better choice if you don’t need to be straight when cutting.

After the carbon fiber composite sheet has been cut, it is often necessary to smooth the carbon fiber to ensure success. This article shows the cutting process of carbon fiber composite sheets in comic form.

1. Preparation before cutting

-

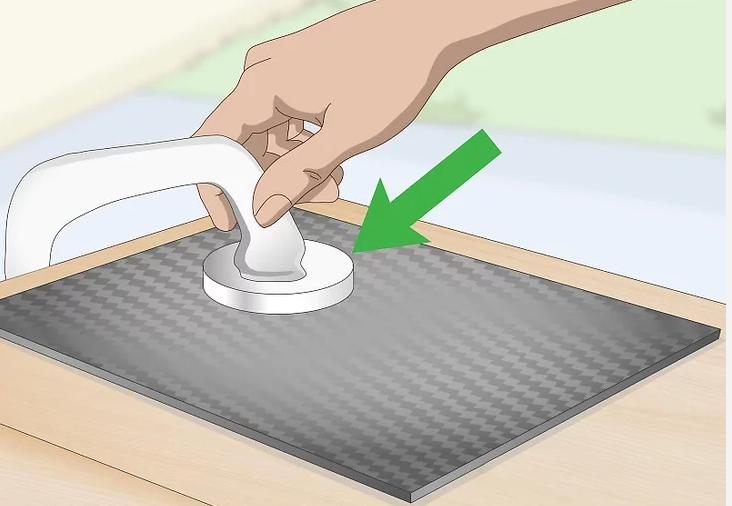

Clamp the carbon fiber sheet on the workbench

Having a drop-down table works great because the carbon fiber dust can be sucked away as it is created using the built-in ventilation system. If there is no drop table, the carbon fiber must be cut on a flat table top. Use clips or a vise to hold the carbon fiber in place.

-

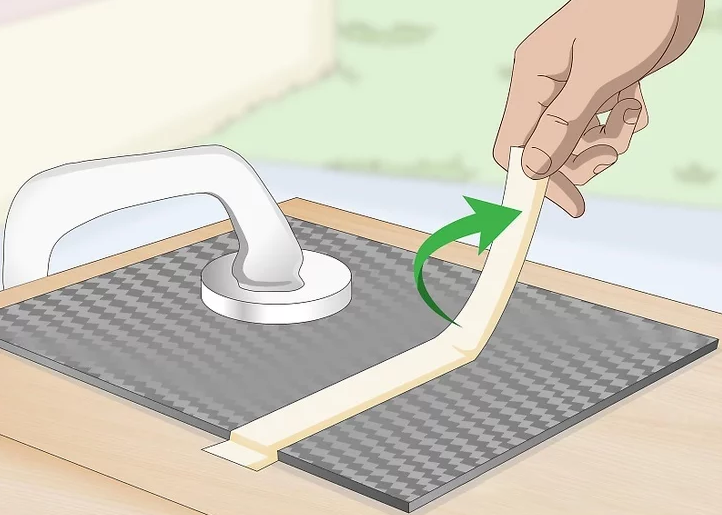

Cover the area to be cut with tape

Carbon fiber sheets are mostly black, so ordinary pencil marks are difficult to show on carbon fiber. First, measure out the planned cut with a ruler, then lay down multiple strips of tape to form a border around the area to be cut. This works especially well for round surfaces such as carbon fiber tubes; marking tools such as silver permanent markers can also be used, which can be combined with tape for greater precision.

-

Wear dust protective equipment

Wear a dust mask and goggles to avoid carbon fiber dust. Although carbon fiber dust is non-toxic, it can still irritate the eyes and lungs, so before cutting carbon fiber, you should always wear good protective gear and ventilate the area as much as possible to eliminate dust. A vacuum hose can also be set up near the workbench to pick up dust while cutting the carbon fiber.

Wear gloves to prevent cuts

Cut carbon fiber is usually very sharp, so be prepared with a pair of reinforced gloves. Plus, longer gloves stop carbon fiber dust from accumulating under your nails and between your hands. Wearing long sleeves can help protect the rest of your body, and if you plan to cut a lot of carbon fiber, wearing gloves will be very helpful. If carbon dust does accumulate on the skin, it may sting and the area should be rinsed immediately with cold water.

2. Cutting with a Rotary Tool

-

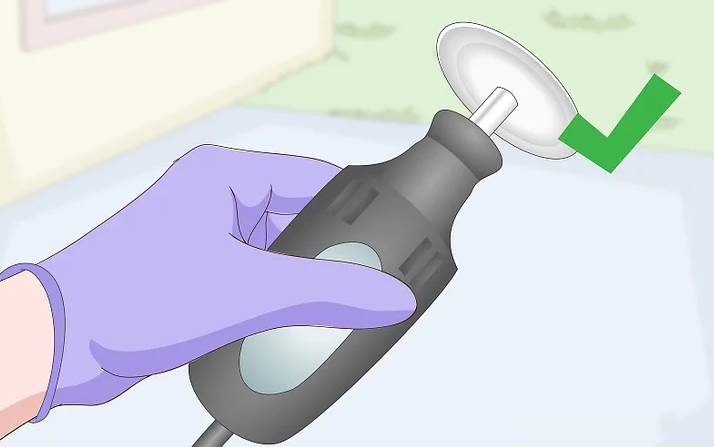

Getting ready for cutting

Choose from diamond or tungsten carbide cutters, or use a variety of common rotary tools to cut carbon fiber, including Dremel, pneumatic rotary, router or angle grinder. But no matter what you choose, make sure that the wheel or wheel listed is an abrasive or grit type. Smooth wheels and drums are less likely to seize or overheat than toothed wheels and drums. Any wheel or drum designed for cutting metal will work.

-

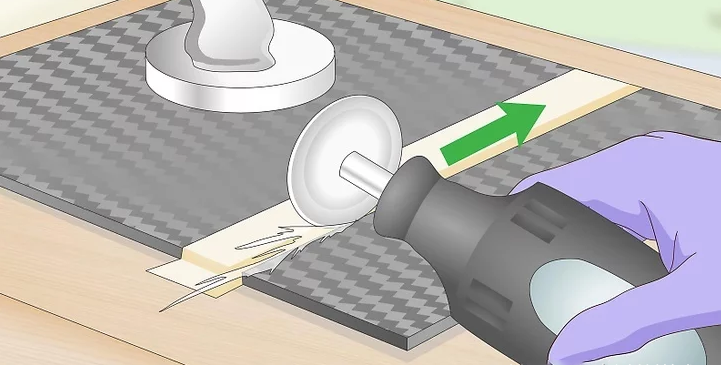

Cutting carbon fiber

After the carbon fiber sheet is placed on the cutting surface, the rotating wheel is placed on it; when cutting, it can be cut directly along the guide lines traced on the carbon. Hold the saw on the side of the line closest to the part you want to discard. When the rotary tool is all the way through the carbon fiber, continue to move it along the part until the cut is complete.

-

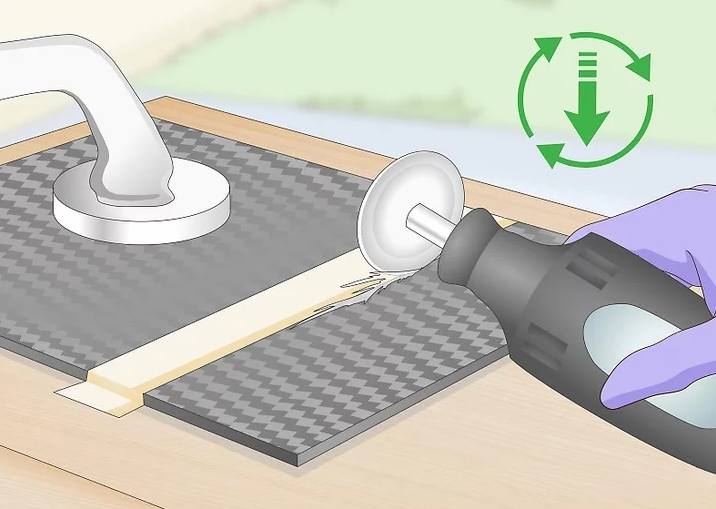

Reasonable speed control

If the blade starts to overheat, the speed should be reduced. This usually occurs when the rotating tool has difficulty penetrating hard fibers, especially with ordinary metal wheels. Some signs of overheating are harsh squeals, loss of cutting power, burning smell or smoke. If you suspect that the tool is overheating, remove it from the carbon fiber and turn it off until cool.

Sand the cut with sandpaper

Smooth the cut with 180-grit sandpaper, briefly rubbing down the edge of the cut to level the cut, removing excess material around the guide lines you are following, also eliminating any sharp edges. When you're done, inspect the carbon fiber carefully for any unevenness and smooth it out.

3. Cutting with a saw blade tool

-

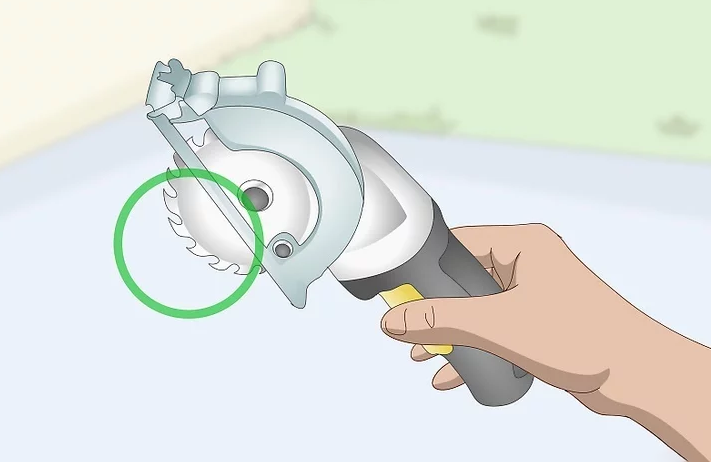

Getting ready for cutting

It is best to choose a saw with a tungsten carbide grit style blade. The serrations are the biggest problem with cutting carbon fiber with a saw, blades with large teeth will break the carbon fiber, while blades with small teeth will clog the resin and wear out faster. Your best bet is a harder blade with finer teeth or no teeth at all, and designed to work with metal or carbon fiber, you can use jigsaws, saber saws, or even handsaws with tungsten carbide grit-type blades.

-

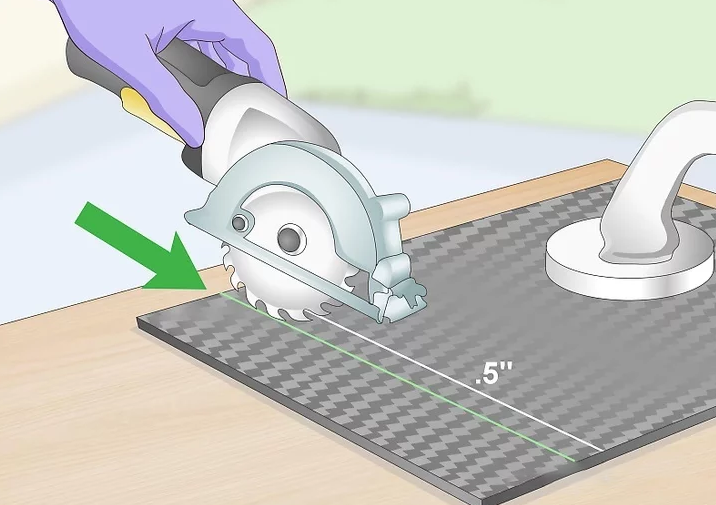

Saw blade positioning

Position the blade 1/2 inch (1.3cm), since saw blades cause more chipping than rotating tools, try to position the blade a little further from the line if possible.

-

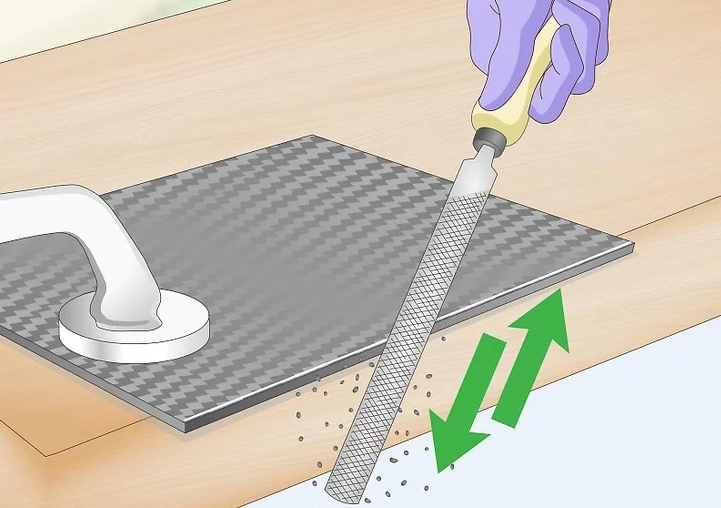

Scrub off excess material with a file

Use a metal file to remove excess material from the cut edges, when finished, the edges should look smooth and even; you can also use a block of sandpaper, such as a coarser 120 grit to grind off excess carbon fiber, while a finer 180 Rough surface to smooth the edges.