Modulus and tensile strength of reinforcing fibers for composite materials of carbon fiber, glass fiber and Kevlar fiber

- 2022-04-22

Currently, as a common reinforcing fiber for composite materials, there are usually three types: carbon fiber, glass fiber and Kevlar (aramid) fiber.

When used for composite reinforcement, the fiber can define the performance standard of the material and is responsible for the load-bearing role in the design of the structure, while the resin matrix is mainly responsible for transferring the load to the fiber. In short, the choice of fiber type is an integral part of the design process.

For the above three types of reinforcing fibers, there are often thousands of properties that need to be weighed when deciding which material to use for a given project.

When choosing a fiber, factors and characteristics such as fiber modulus, tensile strength, compressive strength, toughness, stiffness, electrical conductivity, and chemical/corrosion

Although there are thousands of material properties to choose from, choosing the right fiber at the beginning of the project design will effectively alleviate the challenges throughout the project and point to the best raw materials. Generally, composite structures use more than one type of fiber to meet the design requirements required for final use. Although there are countless fiber properties that can further define the end use of a structural part, the following advanced features provide advanced features for defining design purposes:

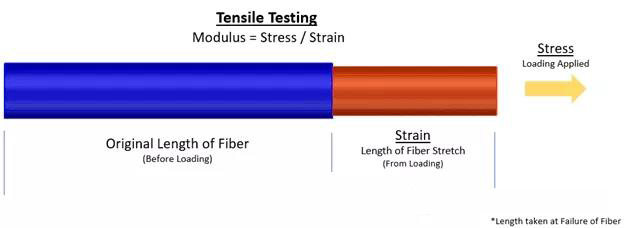

Fiber modulus refers to the length change experienced by the fiber when subjected to increased load.

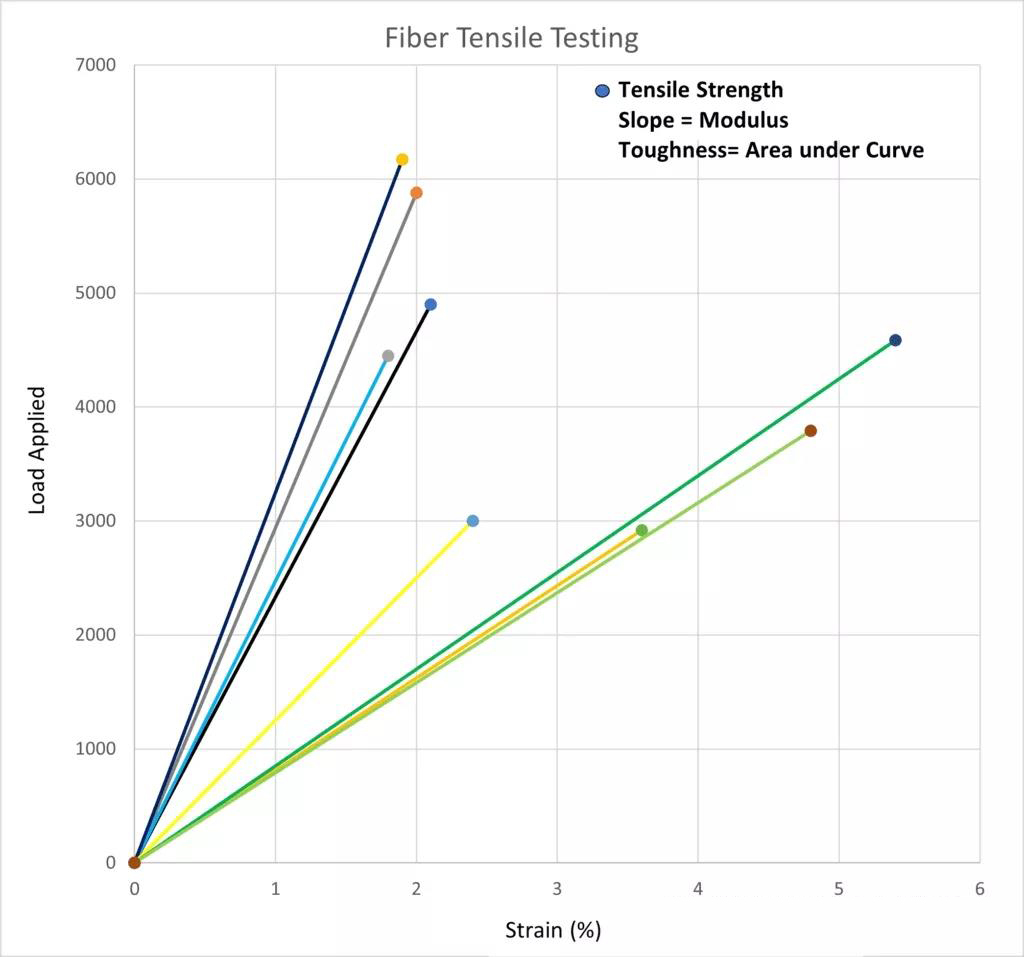

This load can be compressive or tensile. The calculation method is stress divided by strain. The modulus usually indicates the stiffness of the material. On a given stress/strain curve, it is called the slope of the straight line.

Most fibers are classified by modulus because it helps determine the stiffness of the composite material. Generally, composite materials using carbon fiber, glass fiber, and Kevlar are all classified as brittle materials. Compared with more plastic materials or non-brittle materials, there is almost no stretch at break.

Tensile strength is the ability of a material to withstand loads when stretched.

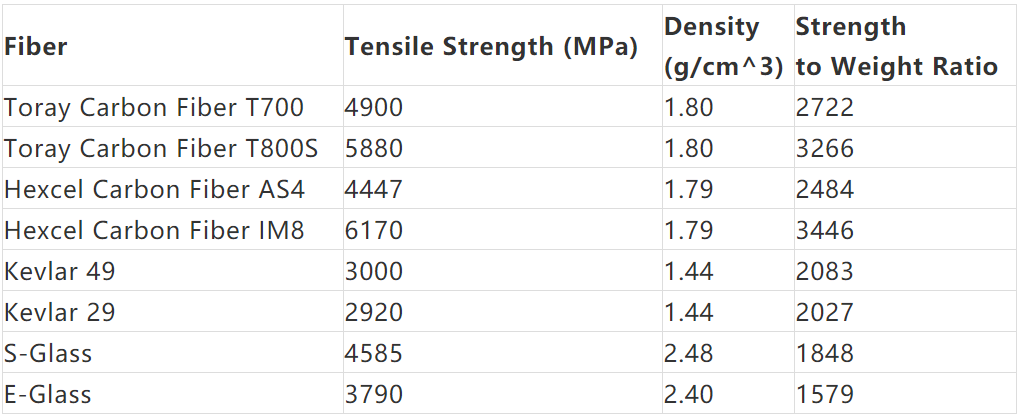

It is the maximum force or load applied before the fiber is permanently deformed. As shown in the figure, carbon fiber has advantages in strength and strength-to-weight ratio. For example, the strength-to-weight ratio of Toray T800S is as high as 3266, which is listed in the table. The highest value of all reinforcing fibers. However, there is a significant difference between S-glass fiber and E-glass fiber.

In terms of density, Kevlar is the lightest material. As shown in the table above, the bulk density of Kevlar fiber is only 1.44g/cm^3. Although Kevlar has the lowest ultimate strength, in terms of strength to weight ratio, it exceeds that of glass fiber, but is slightly lower than carbon fiber. From an economic point of view, if ultimate strength is the only design criterion, then E-glass fiber is the first choice.