If Abe wears UHMWPE body armor, will the situation change?

- 2022-07-13

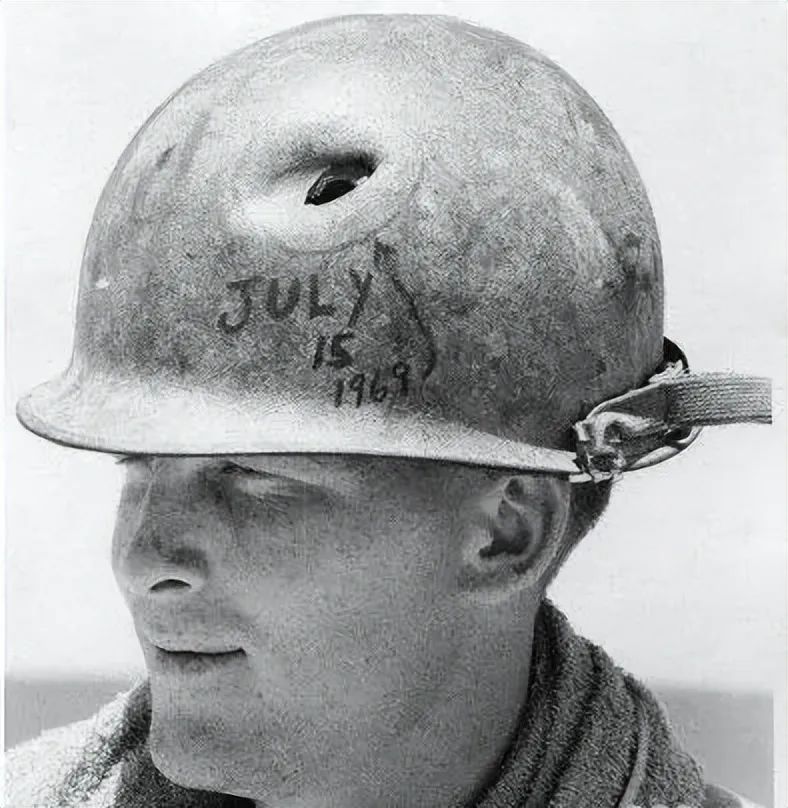

On July eight, former jap high Minister Shinzo Abe died of his accidents after being shot at on the age of 67.

Judging from the live pictures released via major media reviews, Shinzo Abe did not wear a body armor.

At present, my united states of america is the largest manufacturer of bulletproof vests inside the global, and the cloth generation of bulletproof vests has been constantly improving, and the level is also inside the vanguard. Among nearly 200 countries and areas inside the world, there are simplest three manufacturing international locations that can independently whole the whole method from the research and development of frame armor uncooked materials to the of entirety of manufacturing and production, particularly the united states, China and the Netherlands.

It must be stated that in China, bulletproof vests are allowed to be produced with the aid of personal corporations, and the boundaries to international change are not high. Home private companies can absolutely take part in this enterprise. Further, China's bulletproof vests are specially made of PE, this is, ultra-excessive molecular weight polyethylene. This kind of fabric has right protecting impact and coffee fee. At present, the mainstream bulletproof vests and bulletproof inserts and different bulletproof gadget are product of PE.

According to reports, 70% of UHMWPE fibers inside the united states of america are utilized in military fields along with bulletproof vests, bulletproof helmets, bulletproof armor for navy centers and gadget, aerospace and different navy fields. An crucial material basis for a present day and effective country. At present, the united states has vigorously supported and multiplied the improvement of the production and application of ultra-excessive molecular weight polyethylene fibers in my us of a, and home UHMWPE fibers have occupied a pivotal function in the global.

The person became shot at close variety within the photograph, he stated he had some pain, perhaps a little wounded, but was nonetheless upright and awake. Any such body armor probable expenses round $1,000.

The U.S. Army uses plastic in preference to Kevlar to lessen the load of military helmets by means of 24 percent at the same time as maintaining the equal power.

Back then, during global war II, the usa used metallic helmets to guard the head, and the development of the military industry with plastic rather than steel have to now not be underestimated.

What plastic can update Kevlar for bulletproof?

It should be our polyolefin fabric, particularly ultra-high molecular weight polyethylene fiber.

Today we are going to speak about ultra-excessive molecular weight polyethylene (UHWMPE).

UHWMPE is a thermoplastic material with a linear structure. It has overall performance akin to engineering substances. The general viscosity common molecular weight is above 1.5 million, and the burden average molecular weight is above 3 million. Performance, corrosion resistance, light weight and other houses.

Its maximum outstanding area is its mechanical houses

-

Super friction resistance

The friction resistance of UHWMPE is proportional to the molecular weight, which exceeds that of carbon metallic, PA66 and different conventional substances.

-

Sturdy impact resistance

The effect resistance will increase with the increase of the molecular weight, reaches the maximum cost when the molecular weight is 5 million, after which decreases. Of precise observe is the potential to preserve wonderful effect strength even at low temperatures.

-

Exceptional self-lubrication

The friction coefficient of water lubrication is ready two times decrease than that of dry friction, that's one third of that of PA66 material beneath the same conditions.

-

Low temperature resistance

The embrittlement temperature is normally below -80 stages Celsius, and high impact power and different mechanical properties can nonetheless be maintained among 0 tiers Celsius and -40 ranges Celsius

Excessive tensile electricity

Fiber products via the gel spinning technique have a tensile energy of 3-15GPa and a tensile elastic modulus of 100-125GPa, which is four instances that of carbon fiber and 10 times that of metal twine.

The drawback of UHMWPE is that it has negative warmth resistance, terrible compressibility, flammability and certain creep.

Due to its excellent mechanical properties, UHMWPE has been utilized in countrywide defense, clinical and health, aerospace, marine, and so on. The goods also encompass pipes, movies, medical implantable bones, fibers, etc.

UHMWPE development records

UHMWPE resin turned into first evolved and industrialized by using Hearst employer in Germany in 1958. Seeing that then, Hulksler inside the united states, Mitsui chemical compounds in Japan, and DMS in the Netherlands have successively finished huge-scale business manufacturing.

At gift, the arena's biggest manufacturer of UHMWPE raw materials is TICONA, which is owned with the aid of Hearst institution, observed via Montell inside the united states of america, followed with the aid of DMS in the Netherlands.

Domestic UHMWPE fiber development

My country began to analyze and increase UHMWPE fibers within the Eighties. At present, it has emerge as the 1/3 biggest u . S . In UHMWPE fiber manufacturing. The research consequences of the Chemical Fiber research Institute of Donghua university have enabled my u . S . A . To apply this ultra-excessive-strength fiber to the recycling device of the "Shenzhou" spacecraft. The college has evolved high-attention dope spinning technology and built a manufacturing line with an annual output of 250 t in step with line, making my us of a a rustic with impartial intellectual property rights to provide UHMWPE fibers after the us and the Netherlands.

UHMWPE is already an critical fiber fabric in a few fields, however it is simple that this fabric nevertheless has a number of room for research and improvement. It also has shortcomings such as excessive creep, bad interfacial bonding and high cost. There is additionally large research and development capability. As an instance, the theoretical strength of UHMWPE fiber can be increased by means of 7 to eight times compared with current fibers. Consequently, it's far necessary to keep to discover and improve the modification method to enhance the overall performance of UHMWPE fiber and supply full play to its superior performance, so that UHMWPE can be implemented to more fields.