What is advanced fiber material?

- 2022-05-19

In addition to traditional textiles and clothing, household goods and other consumer goods, fiber material products are also widely used in transportation, environmental protection, safety protection, geotechnical engineering construction, medical and health, aviation, aerospace, national defense and other fields. At present, domestic advanced fiber materials mainly refer to different functional fibers, high-performance fibers, advanced bio based fibers and advanced ceramic fibers.

Differential functional fiber

Differential is a general concept. It refers to fibers with some special functions in addition to the existing characteristics of traditional fibers. In the preparation of conventional chemical fibers such as polyester fiber, polyamide fiber, regenerated cellulose fiber and polyacrylonitrile fiber, one or more molecular modifications, addition of functional components, special spinning molding and fiber post-treatment are comprehensively used. Prepare in various ways. Compared with traditional chemical fibers, this kind of fiber can significantly improve or improve the properties and functions of fibers. Anti-static fibers, such as far-infrared fibers, anti-ionic dyes, graphite fibers, anti-bacterial fibers, anti-ionic fibers, and so on.

High performance fiber

At present, the development of high-performance fibers in China mainly focuses on carbon fibers, polyacrylonitrile pre oxidized fibers, aramid fibers, ultra-high molecular weight polyethylene (UHMWPE) fibers, polyimide (PI) fibers and polyphenylene sulfide (PPS) fibers.

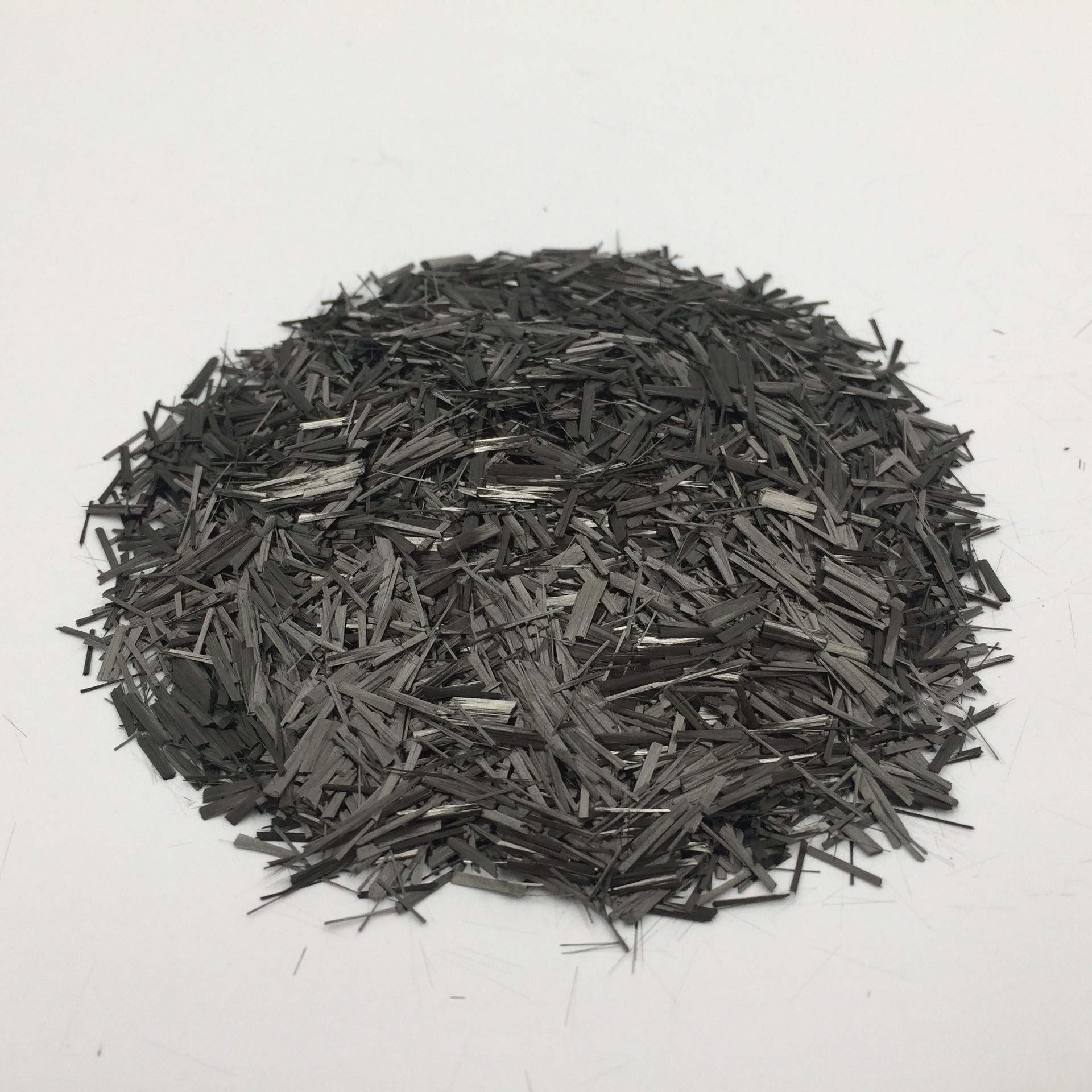

1. Carbon fiber

A special fiber made of carbon. At present, there are viscose based carbon fiber, asphalt based carbon fiber and industrial polyacrylonitrile (Pan) based carbon fiber. Polyacrylonitrile based carbon fiber is the current mainstream technology, and domestic carbon fibers are basically polyacrylonitrile based. Carbon fiber has the characteristics of high temperature resistance, friction resistance, conductivity, heat conduction and corrosion resistance. Strength and modulus. Carbon fiber has low density and high specific strength and modulus. The main purpose of carbon fiber is to composite with resin, metal and ceramics as reinforcement to manufacture advanced composites. Carbon fiber reinforced epoxy resin composites have particularly high strength and specific modulus.

Pre oxidized PAN fiber

Pan pre oxidized silk is an important intermediate for the preparation of carbon fiber. As a flame retardant material, pre oxidized silk has many advantages of carbon fiber products, and the cost is lower than that of carbon fiber. PAN based pre oxidized silk not only has excellent flame retardant and heat resistance, but also the chemical resistance of the fiber is better than that of ordinary synthetic fiber. PAN based pre oxidized silk is a new type of heat-resistant and flame-retardant material with the development of carbon fiber. The processing performance and wear resistance of the fabric, and asbestos has no harmful effect on human body. Polyacrylonitrile based pre oxidized fiber can be used in building thermal insulation materials, pipeline thermal insulation materials, high-temperature furnace thermal insulation materials, fire-proof clothing and flame-retardant decorative materials, sound insulation and thermal insulation materials, etc. it has remarkable economic and social benefits. It has become an independent material variety and has been put on the market. The demand is increasing day by day, and the market prospect is good.

Application of Pan pre oxidized fiber: application of fireproof clothing and flame retardant decorative materials. Protective clothing is insulated and flame retardant. It can be used in fire disaster relief clothing, combat clothing, high-temperature operation in front of the furnace, welding, cutting and other working environments, as well as military, navy and special police combat clothing. As a special fabric, polyacrylonitrile based pre oxidized silk can be widely used in the inner coating and outer cover of aircraft and automobile seats, as well as the inner flame retardant protective layer of furniture because of its good flame retardant performance; It can also be used for ships and passenger ships. Hotel mattresses, sheets, curtains, etc., as well as stage curtains and furniture. The flame retardancy of Pan pre oxidized yarn is more cost-effective than aramid.

3. Aramid fiber

The full name of aramid fiber is "aramid fiber", and the English name is Aramid fiber (DuPont's trade name Kevlar is a kind of aramid fiber, that is, para-aramid fiber), and the word "aramid" is "polyamide fiber". Abbreviation for aramid. Polyaramid was first used commercially as meta-aramid fiber in the early 1960s, while para-aramid was born in the 1960s and 1970s. Aramid has excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, light weight, etc. Its strength is 5 to 6 times that of steel wire, its modulus is 2 to 3 times that of steel wire or glass fiber, and its toughness is that of steel wire. 2 times the weight of the steel wire, and the weight is only about 1/5 of the steel wire. At a temperature of 560 degrees, it will not decompose or melt. It has good insulation and anti-aging properties and has a long life cycle. Aramid fiber is also an important national defense and military material. In order to meet the needs of modern warfare, the bulletproof vests of developed countries such as the United States and the United Kingdom are made of aramid. The lightweight of aramid bulletproof vests and helmets has effectively improved the rapid response capability of the army. and lethality. At present, domestic aramid fibers are mainly used in high temperature filtration, protection, sealing and other materials.

4. Ultra high molecular weight polyethylene fiber (UHMWPE fiber)

Ultra high molecular weight polyethylene fiber (UHMWPE), also known as high strength and high modulus polyethylene fiber, is a fiber made of polyethylene with molecular weight between 1 million and 5 million. Its specific strength is more than 10 times that of steel wire with the same section, its specific modulus is second only to super carbon fiber, and its impact absorption energy is almost twice that of aramid fiber. It has good wear resistance and low friction coefficient. Due to its many excellent properties, UHMWPE fiber shows great advantages in the high-performance fiber market, from mooring lines in offshore oil fields to High-Performance Lightweight composites in modern war and aviation. Aerospace, maritime defense equipment and other fields play a key role. It has the advantages of softer and bulletproof than aramid, and has become the main fiber occupying the bulletproof vest Market in the United States.

5. Polyimide fiber

Polyimide fiber is a kind of high-performance fiber. It is polymerized by hot metal dianhydride and aromatic diamine to obtain polyamide acid prepolymer, and then melt spun. Compared with high-strength and high modulus polyethylene, polyphenylene sulfide and other high-performance fibers, polyimide fibers have wider temperature resistance (- 267-550 ℃); Compared with Alami, it has higher heat resistance, flame retardancy and better weather resistance. At the same time, it also has unique comprehensive characteristics such as textile processing and human affinity. Polyimide fiber has good spinnability and can be made into textiles in various special occasions. Polyimide fiber thermal insulation clothing has the advantages of high temperature resistance, low temperature resistance, flame retardant, non droplet, self extinguishing and excellent thermal insulation performance. It is comfortable to wear, good skin adaptability, permanent flame retardant, large volume, stability, safety and long service life. Compared with other fibers, it has low thermal conductivity and is an excellent thermal insulation material.

6. Polyphenylene sulfide fiber

Polyphenylene sulfide fiber, also known as PPS fiber. It is obtained by melt spinning of polyphenylene sulfide. Polyphenylene sulfide fiber has good heat resistance. It is mainly used as high-temperature resistant filter cloth and can withstand temperatures above 190 ° C. the fiber also has excellent resistance to chemical reagents, hydrolysis and flame retardancy. Polyphenylene sulfide fiber has excellent textile processing properties. Its strength and elongation are similar to those of cotton fiber. However, the modulus is low and the moisture absorption is low. The rapid development of bag dust removal technology has driven the development of domestic fiber grade PPS resin manufacturers. Domestic PPS fiber is mainly used in filter material industry.